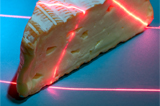

In the light section method, a light line is projected onto the test object and this is recorded with a special camera at an angle to the projection direction.

A height profile is calculated from the course of the light line. By moving the object through the light line, the entire surface can be captured. Shadowing by structures can be avoided by using multiple cameras or lasers.

The light-sectioning method is excellently suited for the fast three-dimensional acquisition of the surface of a test object. Even with a lateral resolution of 0.05 mm, speeds in the range of 1 m/s can be realized, whereby the height resolution can be in the micrometer range. By suitable pre-processing of the data, structures can be detected whose height deviation is less than 1 µm. This makes it possible to sort objects according to three-dimensional geometric features in a very short time.

Applications

In the case of foodstuffs, the surface condition can be easily assessed. If additional color (RGB) or hyperspectral data are added, statements can also be made about the color characteristics of the surface.

The method can be applied in many areas:

- Detection of spoiled fruit

- Sorting of fruits according to size

- Determination of the degree of ripeness of fruits

- Sorting out of grain infested with molds

- Detection of incorrectly placed or printed labels

- Detection of damaged packaging

- Documentation of product status

Fraunhofer Agriculture and Food Industry Alliance

Fraunhofer Agriculture and Food Industry Alliance