Compact Measuring Systems for Rapid Food Tests

Measurement systems for food testing should be deployable on site and provide reliable results in a short time. A compact gas chromatography system developed by the Fraunhofer Institute for Physical Measurement Techniques IPM and Fraunhofer Institute for Molecular Biology and Applied Ecology IME determines volatile organic compounds (VOCs) quickly and reliably. The ethylene measurement system developed by Fraunhofer IPM is capable of continuously monitoring ethylene concentration and thus fruit maturity. These systems are thus well suited for on-site control of food quality.

Portable Gas Chromatography (GC) System

The portable gas chromatography (GC) system uses a sensor array as detector. This array is based on semiconductor gas sensors that detect organic compounds at very low concentrations. For example, fruit ripeness can be determined by typical fruit aromas (e.g. esters). Similarly, meat quality can be determined by compounds that are typical for meat ripeness or for the type of storage. In addition, initial experiments have demonstrated that the gaseous metabolism of bacteria can be detected. In the future, it may therefore be possible to detect microbiological contamination in foodstuffs. Furthermore, the gas chromatography system can be used for monitoring in the food processing industry, e.g. in incoming goods for quality control, in production, during storage or during transport.

Fruit ripeness monitoring

Fruits such as bananas, apples or tomatoes release ethylene during storage and transport. This plant hormone influences the metabolism of neighboring fruits as well as vegetables, accelerates fruit ripening and leads to faster spoilage. By monitoring the ethylene concentration and thus the fruit ripening during storage or transport, the resulting considerable economic damage can be specifically counteracted.

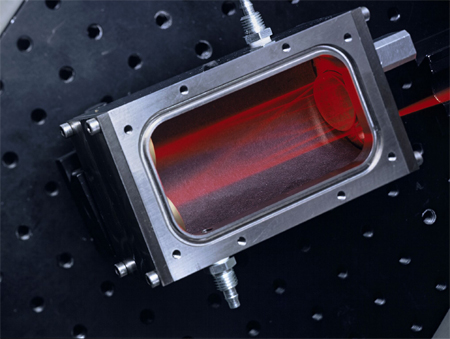

The compact ethylene measuring system is capable of continuously monitoring ethylene concentration and thus fruit ripeness. It is based on a miniaturized filter photometer at 10.6 µm, which consists of an IR emitter, a long-path cell and a detector unit. The measuring system can thus be used to specifically control ripening processes and, for example, to control aeration systems in order to set a low ethylene level during storage or to carry out a controlled ripening process by ethylene gassing.

Fraunhofer Agriculture and Food Industry Alliance

Fraunhofer Agriculture and Food Industry Alliance