One Step Closer to the Food Scanner

The topic of »food scanners« is becoming increasingly important. The European Commission has also recognized the topic as important and is promoting the development of corresponding technologies. As a leading institution for applied research in Europe, the Fraunhofer-Gesellschaft is also involved in the field of food research. For almost 10 years, the Fraunhofer Food Chain Management Alliance has also been active here in the field of spectroscopic food analysis. As part of the alliance, the Fraunhofer Institute for Photonic Microsystems IPMS in Dresden has filed a patent application for an idea that makes it possible not only to analyze food with a smartphone, but also to measure it and calculate its nutritional value.

With its latest patent application, Fraunhofer IPMS is pushing the topic of "food scanners" further: the cell phone is not only to analyze individual food products in terms of their quality, but also to become an individual nutrition and fitness advisor. In addition to determining the quality of a food item, it will be measured using 3D triangulation, allowing the quantity and true nutritional value to be determined. Intelligent algorithms then combine this data with the user's individual parameters (height, weight, etc.) as well as data from motion analysis. From this, the relationship between nutritional intake and consumption is determined, enabling a recommendation to be made to the user.

The underlying technologies have been known for a long time. As industrial solutions, they are used, for example, to measure the degree of ripeness or the sugar content of fruit. However, each of these applications is a solution to a specific problem. Of particular interest for widespread use, however, are the flexible application possibilities of the so-called food scanners. For this purpose, information that today can only be determined in complex laboratory analyses must be brought to the user's cell phone. This is the task of microsystems technology.

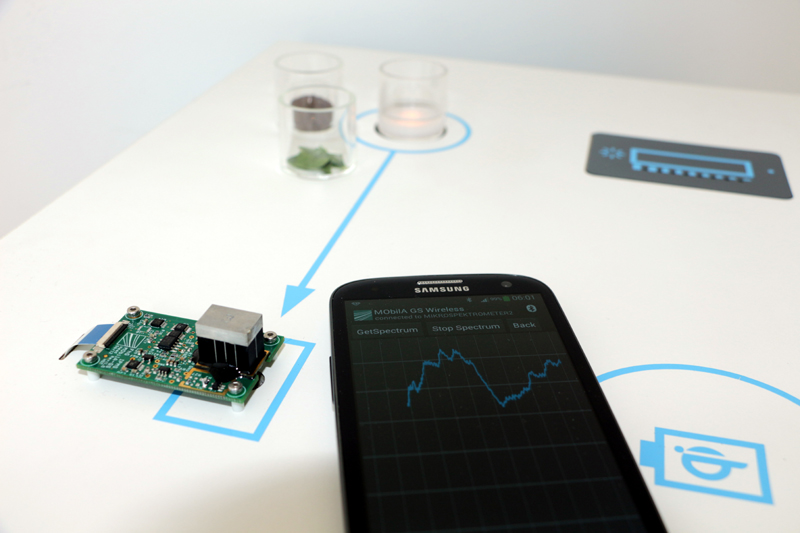

Additional hardware component

Deeper information about the composition, such as statements about the degree of ripeness of fruit, the freshness of vegetables or the actual fat and protein content of pieces of meat, can be recorded without contact using high-quality spectral analysis methods in suitable spectral ranges. These and other important bands of organic compounds in food are located in the near-infrared spectral range above 750 nm, which cannot be measured due to the silicon camera chip as well as the common camera configuration (IR filter) and the integrated illumination technology in conventional cell phone cameras. Therefore, in addition to the camera, another hardware component is needed that is capable of performing spectral analytical measurements. These are among the contents of current work and patent applications of the Fraunhofer IPMS.

The laboratory on the phone

Approaches are already under development to build miniaturized systems directly into the cell phone in order to be able to use the system components directly. At present, however, the size in particular is still a challenge, since cell phone manufacturers demand a maximum height of 4.5 mm. Such technologies are being developed at Fraunhofer IPMS with its special processes for manufacturing extreme miniaturization.

More than a question of hardware

In order to generate useful information from a spectral measurement, a number of influencing variables must be considered when evaluating the data. For example, factors such as the type and construction of the sensor as well as differences in illumination or measurement position must be taken into account. In addition, the evaluation must also take into account the variability of the "spectral fingerprint" of the measured products. For example, the reflectance bandwidth of fat in beef differs from that of fat in cheese or in fish. The same applies to proteins and carbohydrates. Compensation for these influencing variables requires prior knowledge that is adapted according to the respective measurement. The complex evaluation of food measurements therefore requires software-based evaluation routines and reference data from an extensive database that are constantly verified and updated by reference analyses, such as those developed by the Fraunhofer Institute of Optronics, System Technologies and Image Exploitation IOSB in Karlsruhe.

Interdisciplinarity is in demand

In addition to expertise in microsystems technology, laboratory-based reference analysis is crucial. Precise knowledge of the complex food matrix is crucial here. The Institute for Molecular Biology and Applied Ecology IME in Schmallenberg provides important benchmarks in food analysis with its expertise in sampling, sample preparation and chromatographic trace analysis.

This synergy is unique so far.

In parallel to statements on quality and nutritional parameters, the contamination of foodstuffs is also the subject of constant critical discussion: be it due to mold, microbiological degradation products ("rotten meat") or chemical substances (environmental contaminants, pesticides). In this area, however, the required detection limits are so small that rapid analysis using, for example, special methods such as fluorescence or Raman spectroscopy would be conceivable. The Fraunhofer Institute for Reliability and Microintegration IZM is working intensively on the cost-effective miniaturization of such systems in order to make such applications accessible to a broad target group. It is therefore conceivable that in the foreseeable future it will be possible to bring all the components together and, via correlation and networking, provide information that is currently only accessible in specialized laboratories.

Contact: heinrich.grueger@ipms.fraunhofer.de

Fraunhofer Agriculture and Food Industry Alliance

Fraunhofer Agriculture and Food Industry Alliance